The domestic epidemic has been controlled, people's lives are slowly returning to normal, they can work with peace of mind, and they can go out in their spare time and pick up stories. Business work also began. Today, Rongchang bearing workshop produces a new product: self-lubricating joint bearings, what is joint bearings?

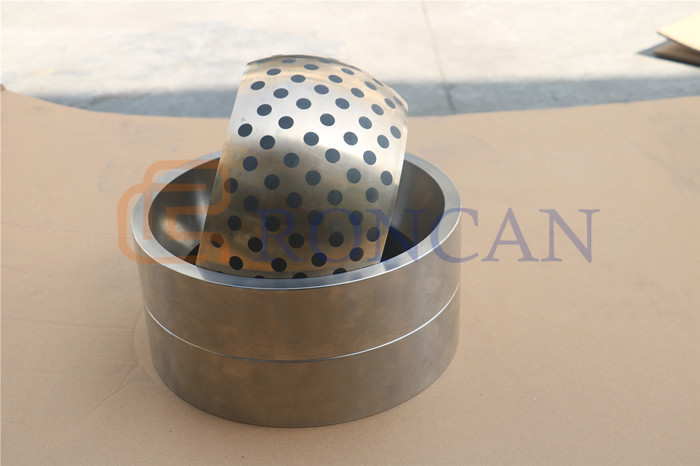

The outer ring of the bearing is a steel sleeve, and the inner layer is a solid Mosaic bearing, which is on a high force brass matrix. A high-performance solid lubrication product inlaid with graphite or mos2 solid lubricants. It breaks through the limitations of general bearings relying on oil film lubrication. In the process of use, through the friction heat to make solid lubrication and shaft friction, forming excellent conditions of oil and powder lubrication, it can replace the traditional flange linear motion bearing, linear sliding bearing not only protect the shaft from wear, but also make the solid lubrication characteristics eternal. Knuckle-bearing is a spherical plain bearing, its sliding contact surface is an inner sphere and an outer sphere, which can rotate and swing at any Angle when moving, it is made of surface phosphating, blasting, insert pad, spraying and other special process processing methods. Joint bearing has the characteristics of large load capacity, impact resistance, corrosion resistance, wear resistance, self-aligning, good lubrication and so on.

Knuckle bearings are widely used in engineering hydraulic cylinders, forging machine tools, construction machinery, automation equipment, automotive shock absorbers, hydraulic machinery and other industries. Joint bearing is a spherical plain bearing, according to its structure and type, can withstand radial load, axial load, or radial and axial simultaneous action of the combined load.

Because the spherical sliding contact area of the knuckle-bearing is large, the inclination Angle is large, and because most of the knuckle-bearing adopts special process treatment methods, such as surface phosphating, galvanized, chrome plating or external sliding surface lining, inserts, spraying, etc., it has a large load capacity and impact resistance. It has the characteristics of corrosion resistance, wear resistance, self-aligning, good lubrication or self-lubrication without lubricating dirt pollution, and can work normally even if the installation is misplaced. Therefore, joint bearings are widely used in low speed swing motion, tilt motion and rotary motion.